What better way to celebrate Independence Day than to write about the ingenuity of the U.S. inventors and things that can go boom?

So what do you get when you mix alcohol, testosterone, gambling and gunpowder? A saloon. Now mix in spherical ivory alternatives that strike each other and what do you have? You have a crowded saloon.

In the mid-1800’s a $10,000 reward was raised by Phelan & Collander, one of the largest billiard ball manufacturers for the first usable ivory alternative. John Wesley Hyatt, most likely spurred by this, not only came up with an alternative, but also created processes that would create perfectly round billiard balls. (Site down for maintenance as of the writing of this article, see the “wayback machine” for an archived version of this)

Celluloid was one of the first plastics to be used in place of elephant ivory. The Hyatt Manufacturing Company created billiard balls that were similar to the size weight and resilience of their elephant ivory counterpart. Unfortunately the chemical composition of these new billiard balls had a couple of downsides: they were extremely flammable, exploding with the sound of a gunshot when a careless cigar or ash came in contact with them (there are stories of everyone in the saloon drawing their guns due to this fact), and they would form a paper thin skin that dust and dirt would adhere to. By mixing camphor in with the ground cellulose nitrate and adding heat, they were able to make a more stable compound.

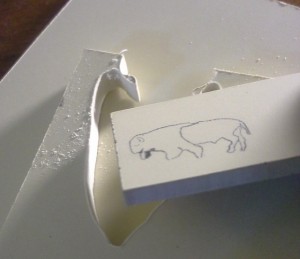

Celluloid from this period was used to make many items that were popular in the day which tortois, ivory and wood were made of, including dolls, toys, handles for every conceivable item including razors, combs brushes and more. It was also useful as an alternative to ivory in the luthier trade.

Today, celluloid nitrate is still available but it is considered a hazardous material due to it’s flammable nature. You can find it in various forms from 0.020” thick to 0.25” thick.

It’s flashpoint is 165 degrees C (329 degrees F).

You can still get this material if you wish from Axiom, Inc.